COKE BATTERIES

HUTNÍ PROJEKT Frýdek-Místek is able to prepare different types of coke oven batteries and pilot coking furnace in relation to the dimensions of the chamber and method of heat tracing or ducts. In the past we addressed these types of batteries:

- Classic coke oven batteries:

COBS5-HP Top with a charge operation, chamber 5.0m high

COBS7-HP large-spaced with Top-charge operation, chamber 7.1 meters high

COBP-HP with stamp charge operation, chamber 3.6m high (0.44 m width of the chamber)

COBP2-HP with stamp charge operation, chamber height 3.5m (0.515 m width of the chamber)

COBP5.5-HP with stamp charge operation, chamber height 5.5m

- Batteries of Heat Recovery /Non Recovery/ types

HR battery with a height of 2.66m the chamber in the crown and a width of 2.75m the chamber with the lower flue gas including the entire energy delivery for heat recovery of flue gas to produce steam or electricity.

- Pilot Ovens (testing ovens)

PO500-HP for approx 500 kg coal charge. Simulation of carbonisation process with oven wall pressure determination. Gas cleaning system facilities. Stamp charge operation, simulation of density for top charge available.

PO250-HP for approx 250 kg coal charge. Simulation of carbonisation process with oven wall pressure determination. Gas cleaning system facilities. Stamp charge operation, simulation of density for top charge available.

PO60-HP for approx 60 kg coal charge. Simulation of carbonisation process with oven wall pressure determination. Gas cleaning system facilities. Stamp charge operation, simulation of density for top charge available.

- Sole Heated Oven (SHO)

The SHO test furnace for measuring of expansion of coking coals. The SHO furnace is designed in a two-chamber design with electric heating of the furnace bottom.

The capacity of each chamber is 6kg of coal.

The operation of the furnace is controlled automatically and the test results are recorded in a connected industrial PC.

Leaflets of the company:

Quenching tower brochure

Coke quenching

- Installation of quenching tower WQ20-HP used to reduce dust emissions from the quenching tower into the air below BAT limits (20g/tcks)

Laboratory equipment – Dasfos

System RF – 33 for determining of the reactivity and strength coke test CRI – CSR

System RF – 33/KK for production of 10kg of coke and determining coke properties CRI – CSR

System RF – 33/TV for determining of coke properties CRI – CSR with thermos-weight with reproducibility 0,5 g.

Plastometer PF – 22 – plastometer by Gieseler as per ASTM D 2639

Dilatometer DF – 7 – as per norm ISO 349, DIN 739, ISO 8264

Supervision during the lining of coke oven batteries

- Technical supervision of the implementation of refractory linings as per project documentation

- Technical supervision of the technological equipment assembly related to the downstream refractory brickwork

- Supervision of comprehensive tests during a running-operation

- Complex activity cover activity of acceptances of refractory

Drying and heating-up coke oven batteries

- Drying and heating-up of coke oven batteries using thermocouples with wireless technology for data collection

- Laboratory of dilatometer tests and chemical composition of refractory

- Elaboration of drying curve

Regulation of the anchoring ties of coke batteries

- Checking & control activity via regulating the anchoring as per to project documentation

Temperature and pressure control of coke oven batteries

- Measurements of temperature, flue gas analysis and adjustment of the pressure modes

- Optimization of thermal regime with respect to emissions and battery age

Audits of coke oven batteries

- Measurement of the temperature and pressure conditions

- Measurement of flue gas analysis

- Measurements of tightness masonry coke batteries

- Check for damage to the brickwork and flue chambers

Services offered in the chemical industry

- The determination of the balance of existing and new technologies

- Optimization of technological hubs

- Proposals for new technological equipment (ChemCAD)

Offered technological nodes

- Coarse and fine condensation

- Primary and final gas cooling

- Tar separation from the coke oven gas (electrostatic or mechanical filters)

- Gas transportation

- Washing out of BTX hydrocarbons from coke oven gas

- Processing of phenol-ammonia plants, including biological wastewater treatment plant

De-sulphurization technology

By Ammonia

- H2S in the purified coke gas ≤ 0.4 g / Nm3

- NH3 in the purified coke gas ≤ 0.03 g / Nm3

- The product desulfurization, sulphur is a purity of 99.9%

Vacuum carbonate

- H2S in the purified coke gas ≤ 0.1 g / Nm3

- NH3 in the purified coke gas ≤ 0.03 g / Nm3

- Desulphurization product is sulfuric acid having a purity of 94% or sulfur having a purity of 99.9%

Oxidation (Stretford)

- H2S in the purified coke gas ≤ 0.05 g / Nm3

- NH3 in the purified coke gas ≤ 0.03 g / Nm3

- Desulphurization product sulphur having a purity up-to 98.5%

Offered machinery in greater detail:

Cokery:

- Machines for coke oven batteries for top charge & step charge operation

- Operating machines of coke oven batteries

- Coal and coke service

Machines for bulk handling operation:

- Scrapers

- Gantry belt stackers and gantry bucket-chain reclaimers

- Bucket-wheel stacker/reclaimers

- Grab cranes

Raw material (coal and ore) processing plants:

- Complete solution from input of mined out material to the sorted material shipment

Coal handling of heating and power plants:

- Complete solution of fuel transport from input (tilt) to the boilers

Bulk material storage, handling and preparation:

- Complete solution of storage including material conveyance lines

Processing plant raw materials (coal and ore)

- Complete solutions from entering mined product, after sorting generic expedition

Coaling heat and power plants:

- Complete transport solutions from arrival (tilt) to transport fuel for boilers

Storage, handling and preparation of raw materials – solids:

- complete solution including storage, transport routes

These units are assembled from particular machines and equipment that are offered separately as a part of repairs, modernization, etc. it is for example:

- Machine, wagon and car carriages

- Drive units and systems (chain and rope)

- Pressureless and pressure piping systems and pipelines customized according to the customer’s specifications (circular, shaped, special)

- Pressure water pumping and distribution systems

- Cranes and lifting gear

- Equipment for breaking of frozen load on wagons

- Transfer ladle and scrap cars

The equipment is, of course, provided based on turnkey delivery which includes a solution ensuring compliance with emission limits and environmental requirements including commissioning and handover to the customer.

Dust removal and desulphurization of energy sources

- Dust removal, DeSOx and DeNOx boilers in power plants based on processed Basic Design Licensor

BTP-HP Aquachemie (Biological Treatment Plant)

Design BWWTP for industrial applications to achieve up to 70% re-utilization of waste water technology with the use of membrane separation processes (reverse osmosis)

Venting & Sealing

Prevention of leakage of harmful substances from individual operating facilities into the air with an inert medium (nitrogen)

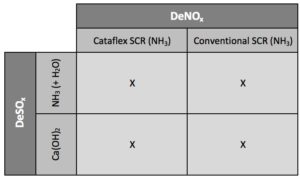

DeSOx and DeNOx – FlueFlex

FlueFlex technology is used for flue gas desulfurization and denitrification of coking batteries. Technology takes place in two main steps:

1) Reduction of SO2 protection technologies DeNOx and achieve the desired SO2 concentration > 30 mg / Nm3 by using semi-dry lime or ammonia method.

2) Denitrification for achieving NOx concentration> 30 mg / Nm3 by means of conventional catalytic methods (catalytic reactor) or a combined device (common filter and the catalytic reactor, a bag filter with an embedded catalyst).

HUTNÍ PROJEKT Frýdek-Místek a.s. gained in recent a few years rich experience in constructions. The biggest orders implemented by our company exceeded 20 millon EUR and demonstrated ability of our ECP team capable of the implementation spread-large and technically demanding construction simultaneously. A relation of technical-level design teams and experienced team of engineering services offering to investors greater value in the ability, flexibly, respond to suggestions from investor in all phases of construction from the creation of project documentation to the stage of actual construction enabling immediate projection of new ideas increases the utility value of the building and representing the savings of spent funds:

Range of our services

- Execution of technological and civil facilities according Project documentation already own by client

- Execution of the construction along with other organization´s teams

- Execution of facilities with direct ties to foreign suppliers according to its documentation

- Coordination of other companies in construction (construction management)

- Commissioning of new projects and technological complexes into operation – the coordination of individual tests, complex tests and pilot operation

Pre-devising preparation

- Complex pre-project & pre-design activities include Investment study.

Design activity

- Documentation as per EIA (Act No.100 / 2001 Sb.), Including consultations

- Documentation IPPC (Act No.76 / 2002 Sb.), Including consultations

- Documentation for “Area approval” (law 501/2006 Coll.) Including Area approval

- Documentation for “Construction permit” (law 499/2006 Coll.), Including Construction permit

- Energy Performance Certificate – PENB

- Site work management

- The documentation for a contractor builder (also in cases of public tenders)

- Documentation for Site Erection (Decree 499/2006 Coll.)

- Documentation of As build, including “RedCorrect” documentation

- All documents are processed and done by an authorized person

The activities during erection

- Presents of authorized supervision

- Presents on behalf of investors technical supervision

- Provision of OSH Coordinator on site (Act No.309 / 2006 Coll.)

- Preparation of documentation for commissioning (operating instructions)

- Participation during commissioning – individual and comprehensive testing, pilot operation

- The preparation of the approval process, including the incorporation of comments from approval committee

Currently is the Designing undergoing a change, not only in the Czech Republic from 2D – drawings to 3D modelling. Our company HUTNI PROJEKT Frydek-Mistek a.s., in thia metter very active and we offer processing of complex projects in 3D.

The use of 3D modelling software

– Advance Steel – Steel structures

– Building Design Suite (Revit) – construction part, HVAC, electrical

– AutoCAD Civil 3D – Road&Transport construction

– Plant Design Suite – piping systems

– CREO (previously ProEngineer) – technological equipment

– EPLAN – electro

Software used for coordination and control of 3D models

– Autodesk NavisWorks

BIM (Building Information Modeling)

– 3D models HPFM contain information about the material, element type, class, etc. pipeline.

– Developing a model 4D = 3D model contains a timeline (Timeliner)

– Developing a model 5D = 4D to model are complemented including construction costs

Product description:

RCAT®-3000

RCAT®-3000 is a nickel-based catalyst on high resistance magnesium oxide carrier, used for decomposition of NH3 in coke oven gas.

Utilization of the catalyst is in ammonia decomposition furnaces upstream of Claus reactors. Catalyst is produced in the shape of Raschig rings with dimensions 20x20x4 cm. As the temperature in ammonia decomposition furnace exceeds 1000 °C, we recommend using the catalyst in combination with ABSM – high purity alumina balls – to extend the catalyst lifetime.

RCAT®-9001

Outlet gas from the ammonia decomposition furnace is further treated in Claus reactors, where sulphur compounds are converted to elemental sulphur. Standard catalyst for the Claus process is alumina based RCAT®-9001.

Process temperature of the Claus reactors is significantly lower than in the case of ammonia decomposition furnace (200-320 °C). Catalyst is supplied in the shape of spheres with diameter 4-6 mm together with high resistance ceramic balls CBSM protecting the catalyst and improving its lifetime.

RCAT®-9002

RCAT®-9002 serves as an alternative catalyst for desulphurization of industrial gases in Claus reactors. In contrast with standard alumina-based Claus process catalyst, RCAT®-9002 contains TiO2 to promote COS/CS2 hydrolysis and to improve overall efficiency of desulphurization process. Even though this catalyst is highly porous, it shows excellent mechanical and temperature resistance. RCAT®-9002 can be used in also in combination with RCAT®-9001.

Oxygen surplus in Claus reactors often leads to a sulphatation of the catalyst. Covering of the catalyst surface with sulphates reduces catalysts activity and overall efficiency of the desulphurisation process.

Increase the catalyst resistance against sulphatation using RCAT®-9003 a RCAT®-9004.

RCAT®-9003

TiO2 based catalyst RCAT®-9003 is produced in a shape of oval extrudates with diameter 3-5 mm. Apart from increased catalytic activity, RCAT®-9003 shows higher resistance against sulphatation. TiO2 based Claus catalyst can be filled in the reactors separately or together with RCAT®-9001 a RCAT®-9002.

RCAT®-9004

Oxygen poisoning of the standard Claus process catalyst can be avoided by using iron promoted catalyst RCAT®-9004. Catalyst improves resistance of standard Claus catalysts. It is produced in shape of spheres with diameter 4-6 mm.

Documents to download: