Category: Chemical plants

Location: Ostrava

Sponsor: OKK Koksovny Ostrava a.s., Czech Republic

Scope of work: Modernizing of Saturator 1A at ammonia plant

Building type/purpose: Reconstruction

Term: 2019

Description:

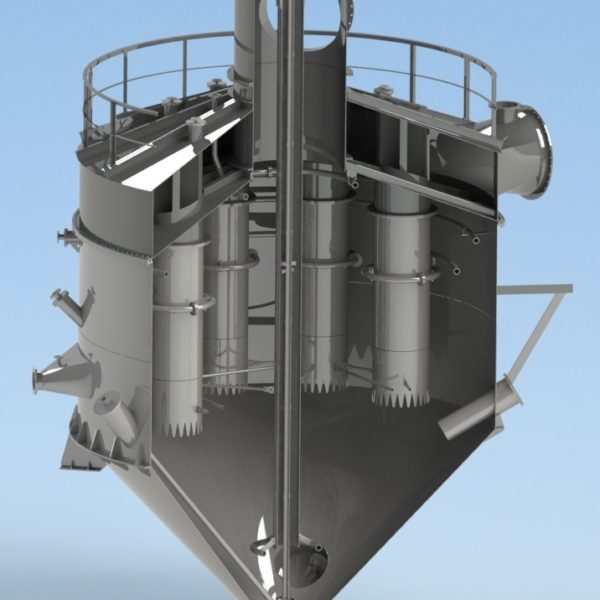

HUTNÍ PROJEKT Frýdek-Místek, a.s. has finished upgrading of Saturator 1A at Ammonia plant in Coke oven plant Svoboda. Modernization of Saturator 1A consisted of disassembly and complete replacement of the lower part of Saturator, incl. its internal built-ins, for new parts. As part of the delivery of new Saturator, modifications were made to other downstream equipment such as caustic and acidic pots. The modernization also included the replacement of downstream pipelines and pumps and the modification of the service steel structure around Saturator 1A.

The uniqueness of the solution lies in the implementation of non-refractory lower part of the Saturator, which is made from materials capable of withstanding the corrosive environment given. Furthermore, the flushing system of the internal part of Saturator was modernized and extended. It is an inner set of rings, perforated pipes and nozzles for cleaning of deposits. For this purpose, a new technology for the preparation of flushing hot water, including high-pressure pumps for its transport, has been proposed and installed.

Also unique is the automatic sulfuric acid dosing system by measuring the acidity of the mother liquor in the Saturator.